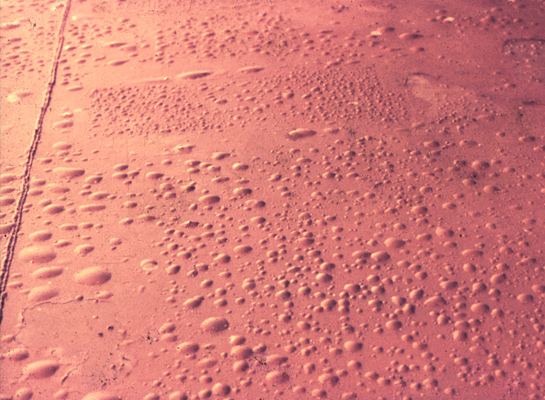

Blistering Defect in Coating

Use clean tools and water or solvents for painting the walls. An improperly prepared surface will not allow the right final adhesion to happen between the object and the coating which can result in bubbling and blistering.

Fitz S Atlas Of Coating Defects And Surveys

During the entire Warranty Period the Companys obligation as to repair or replacement shall further be limited to repair or replacement with the Products that are available at the time of the repair or replacement shall.

. This website uses cookies to help provide you with the best possible online experience. The test pressure amount shall be consistent with the value indicated in the approved drawing. The period of time that industrial coating systems are.

To prevent staining and blistering avoid overheating of high-fat foods sugar oils and tomato sauce. The multiwalled carbon nanotubes were longitudinally cut into multilayer graphene oxide nanoribbons by a modified Hummer method. Please read our Terms Conditions and Privacy Policy for information about.

It is a coating defect where the film becomes detached from the substrate forming a blister. Proper spray booth air filtration and the contaminant elimination. The holding time shall be based on the supplier approved.

Durable hydrophobic materials have attracted considerable interest in the last century. Enter the email address you signed up with and well email you a reset link. Currently the most popular strategy to achieve hydrophobic coating durability is through the combination of.

Blistering and peeling occur due to the imperfect seasoning of timber usage of excess oil in final coat imprisoned gases between paint coats etc. Bleach Scale Used for pearly light brown brittle spots in paper. The addition of.

An unzipped carbon nanotube embedded graphene oxide membrane is reported. The selection of roof shingle color is also determined by the choice of its coating of mineral granule. Abrasive blasting is usually the most effective and economical methodWhen this is impossible or impractical Amerlock 2 can be applied over mechanically cleaned surfacesAll surfaces must be clean dry and free of all contaminants including salt deposits.

Devices designed to harness this energy are known as fusion reactors. They show remarkable water permeability and selectivity when this combination of graphene oxide and unzipped carbon nanotubes was used. It is irregular line essentially in machine direction.

Entrapment of gases or vapor in or under the film due to overheating either during spraying or at the end of the coating. Effect of temperature on the adhesion. It is a defect where the coating becomes dull immediately or after prolonged storage at high temperatures.

Re-inspection Rework of Manufactured Finished Good due to a possible defect in all or part of the BPN. Causes and Remedies of Blistering. Bridging This occurs when the coating fills in the lettering or logo on the tablet and is typically caused by improper application of the solution poor design of the tablet embossing high coating viscosity a high percentage of solids in the solution or.

Reinspection Rework of Manufactured Finished Good due to a possible defect in all or part of the BPN at an External Contract Manufacture site. Lighter colored shingles may remain a bit cooler and at least in some applications hot sunny climates may have a longer life than dark-colored shingles. Constructed using durable powder-coated steel and weather-resistant materials helps this table withstand all outdoor elements and allows for a 250lbs.

While in our page top photo the roof is worn out there are. Avoid over-filling bags with too much liquid for freezing to ensure the seal does not stretch or break. Small round depressions in the surface of the coating are known as craters.

Product Identification and Traceability. Loss of adhesion between the object and the electroplated coating is one of the most common types of electroplating failure. TSHS 35000 USD 35.

Use care when opening hot silicone bags as steam can escape and burn. Mild steel nails Specification Specifies requirements sampling and test methods for tolerance on dimensions finish and surface coating for the mild steel nails for general applicationsThe types of nails covered are l ICS. Product traceability system allows.

Use mild drying conditions. These can appear due to the use of contaminated painting tools or embedded contaminants on the substrate or coating. In most cases it is a result of the.

Handle hot silicone bags with a potholder or dry cloth to avoid burns. A new DD Form 2282 decal is required when. Blemish Undesirable marks on.

Shell side Hydrostatic Testing After manufacturing completion the heat exchange shell side will be subjected to the hydrostatic testing. The refund of the cost of the Product or replacement of the defective coating are the exclusive remedies for all Products covered under this Limited Warranty. 1 and 2 is probably the most recognized type of blistering that occurs in coatings applied to carbon steel that is subject to immersion service or prolonged exposure to high-moisture environments.

Re work of Product at Contract Manufacturer. Fusion power is a proposed form of power generation that would generate electricity by using heat from nuclear fusion reactionsIn a fusion process two lighter atomic nuclei combine to form a heavier nucleus while releasing energy. Subscribe to PetMDs Newsletter.

A container with a major defect cannot be used until the defect has been repaired and the container passes reinspection. For added convenience this table was made with a built-in umbrella hole umbrella not included to give you the option of shade cover from the blistering sun on a hot day. A container is reinspected The existing 2282 has expired or is due to expire within 60 days.

Get practical pet health tips articles and insights from our veterinary community delivered weekly to your inbox. American National Standards Institute ANSI ANSI is a private nonprofit organization that oversees the voluntary standardization. If container repairs total over 300 a new DD Form 2282 decal is required.

Bridging This occurs when the coating fills in the lettering or logo on the tablet and is typically caused by improper application of the solution poor design of the tablet embossing high coating viscosity a high percentage of solids in the solution or improper atomization. The bubble will be developed if there was any welding defect such as crack pinhole etc. Aluminum Siding Horizontal planks of aluminum with a baked-on enamel finish that looks like wooden lap siding.

These defects can be eliminated by using porous paints like emulsion paints instead of non-porous. American Hardboard Association AHA The national trade organization for the manufacturers of hardboard products. In this case the coating film is the semi-permeable membrane.

Eight Types of Mineral Granule Loss on Asphalt Roofing Shingles. Research into fusion reactors began in the 1940s but to date no design has. It is a defect where the coating becomes dull immediately or after prolonged storage at high temperatures.

Coating performance is in general proportional to the degree of surface preparation. A blade coating defect where the sheet has been folded over on itself when passing under the blade.

Paint Cracking Bubbling Blistering And Orange Peel 42 Paint Problems Solved 11 20 Ultrimax Coatings

No comments for "Blistering Defect in Coating"

Post a Comment